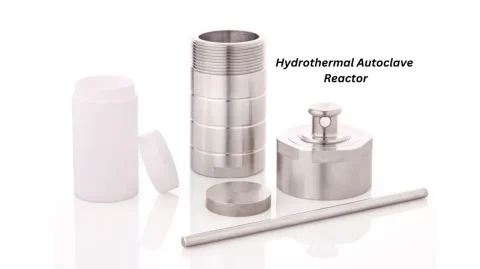

In science and technology, special equipment is vital for many essential processes. It’s called a high-pressure autoclave reactor. Now, what exactly is it, and how does it work? Let’s break it down in easy-to-understand terms.

What’s a High-Pressure Autoclave Reactor?

Think of a high-pressure autoclave reactor as a sturdy, sealed container that can withstand high pressures and temperatures. Inside this container, chemical reactions can happen under extreme pressure, sometimes much higher than we experience daily.

Designing for Safety and Durability:

When engineers design high-pressure autoclave reactors, safety is their top priority. They use strong materials like stainless steel or other alloys that can handle high pressures without breaking. They also ensure the reactor is sealed tight to prevent leaks or accidents. Additionally, they include safety features like pressure relief valves to release excess pressure if things get too intense.

Scaling Up and Down:

Another important consideration in designing high-pressure autoclave reactors is scalability. This means ensuring the reactor can be sized up or down depending on the material being processed. Whether you’re working on a small experiment in a lab or a large-scale industrial process, the reactor should be adaptable to fit your needs.

Heating Things Up:

Temperature control is crucial in high-pressure autoclave reactors. Engineers design them to heat up quickly and evenly, ensuring that reactions happen at the right temperature throughout the reactor. This helps make sure the reaction proceeds smoothly and produces the desired outcome.

Mixing It Just Right:

In some reactions, constant mixing is essential to ensure all the chemicals react correctly. Engineers design high-pressure autoclave reactors with built-in stirrers or mixing mechanisms to keep everything well-mixed throughout the reaction.

Keeping an Eye on Things:

Engineers often include sensors and gauges in high-pressure autoclave reactors to ensure everything goes according to plan. These devices monitor temperature, pressure, and mixing speed, giving scientists and engineers valuable data to control the reaction and make necessary adjustments.

High-Pressure Autoclave Reactors Manufacturer and Supplier:

In Conclusion:

High-pressure autoclave reactors may sound complex, but at their core, they’re all about creating a safe and controlled environment for chemical reactions to happen under extreme conditions. By carefully considering factors like safety, scalability, temperature control, mixing, and monitoring, engineers ensure that these reactors can handle various applications, from basic scientific research to industrial-scale production. So, the next time you hear about high-pressure autoclave reactors, you’ll better understand what they are and how they work!