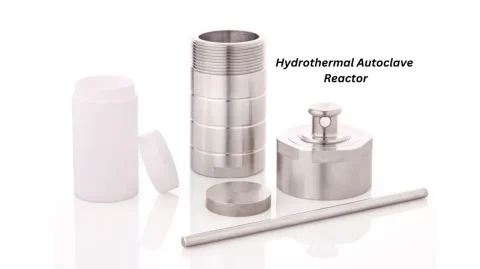

High-pressure autoclave reactors are not just laboratory tools; they’re making big waves in industries worldwide. Let’s dive into some real-life stories where these reactors have transformed industrial processes.

Case Study 1: Pharmaceutical Production

In a pharmaceutical company, researchers struggled to produce a crucial medication due to inefficient reaction conditions. Traditional reactors couldn’t handle the required pressure and temperature. Enter the high-pressure autoclave reactor. Using this advanced equipment, researchers achieved the desired reaction conditions, increasing production efficiency and higher medication yields. The result? More patients received the life-saving drug, all thanks to the innovation of high-pressure autoclave reactors.

Case Study 2: Polymer Manufacturing

A polymer manufacturing plant faced challenges in synthesizing a new type of high-performance polymer. Conventional reactors failed to provide the necessary pressure and temperature control for the complex reaction. Introducing high-pressure autoclave reactors revolutionized the process. Researchers successfully synthesized the desired polymer with improved properties with precise pressure and temperature regulation. This breakthrough paved the way for the development of innovative materials used in various industrial applications, from aerospace to automotive.

Case Study 3: Petrochemical Processing

In the petrochemical industry, engineers were tasked with optimizing the production of a specialty lubricant chemical. Existing reactors needed help to maintain the high pressures required for the synthesis process, resulting in low yields and production delays. By integrating high-pressure autoclave reactors into the production line, engineers achieved remarkable results. The reactors provided the necessary pressure conditions, significantly improving yield and product quality. As a result, the company enhanced its competitiveness in the market and strengthened its position as a key player in the petrochemical industry.

Conclusion

These case studies highlight the transformative impact of high-pressure autoclave reactors in industrial settings. These reactors have revolutionized processes from pharmaceuticals to polymers to petrochemicals, leading to increased efficiency, improved product quality, and more significant innovation. By leveraging the capabilities of high-pressure autoclave reactors, industries can overcome challenges, unlock new possibilities, and drive growth in today’s competitive landscape. With these success stories, it’s clear that high-pressure autoclave reactors are not just tools; they’re catalysts for change, driving industrial progress and innovation across diverse sectors. As technology advances, we can expect more remarkable achievements as high-pressure autoclave reactors continue to push the boundaries of what’s possible in industrial production.

To purchase High Pressure Autoclave Reactors, please follow the links.

1- Techinstro

2- Shilpent