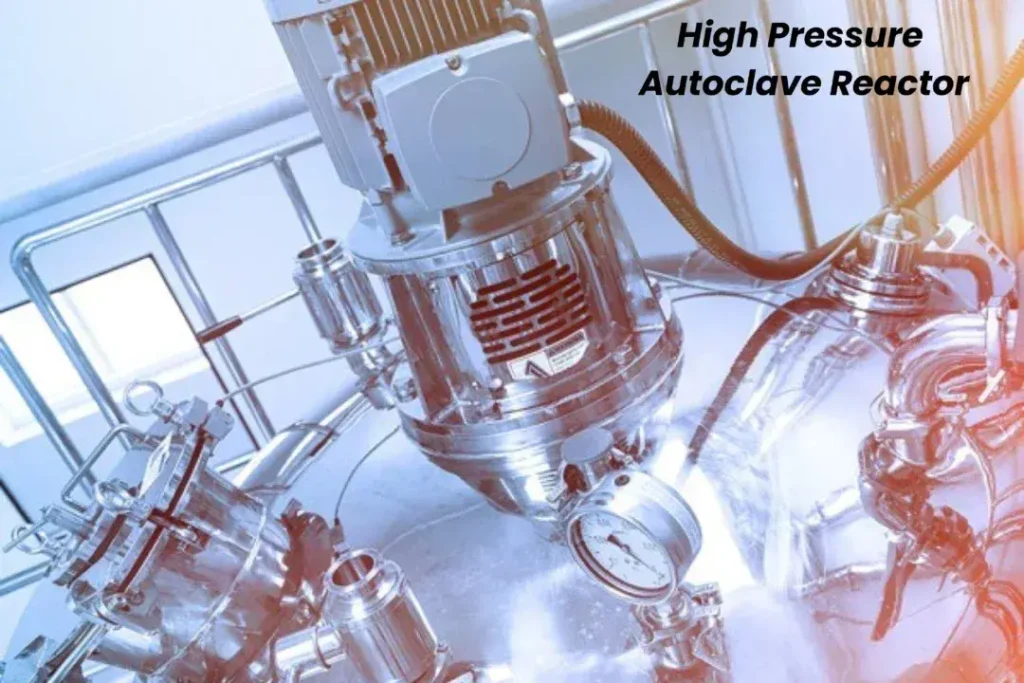

Overview of High Pressure Autoclave Reactors

High pressure autoclave reactors are special machines used to carry out chemical reactions under high pressure and temperature. These reactors are crucial for making certain chemicals and materials that cannot be produced at standard pressure and temperature. By creating high-pressure conditions, these reactors make reactions happen faster and produce more of the desired product. These reactors are commonly used in many fields, including chemical manufacturing, material science, oil refining, and the pharmaceutical industry. They are designed to be very strong and safe, as they need to handle extreme conditions.

Key Principles and How They Operate

Design and Construction

The main part of a high pressure autoclave reactor is its pressure vessel. This is usually a robust, thick-walled cylinder made from stainless steel that can withstand high pressure and heat. The design ensures the reactor remains intact and safe during operation.

Temperature and Pressure Control

Heating elements like electric heaters or steam jackets are used to control the temperature inside the reactor. These keep the reactor at the desired temperature for the chemical reactions. For cooling, systems can be included to manage heat from reactions that release energy.Pressure inside the reactor is controlled using high-pressure pumps or compressors. These inject gases or liquids to maintain the correct pressure. Safety devices like pressure relief valves and rupture discs are essential. They help release extra pressure if it gets too high, preventing accidents.

Monitoring Reactions

Autoclave reactors have sensors and instruments to monitor what’s happening inside. Thermocouples measure temperature, while pressure sensors monitor pressure. Ports for taking samples without stopping the reaction also exist. This real-time data helps operators keep the reaction under control and optimize it for the best results.

Safety Features

Safety is a top priority because high pressure and temperature can be dangerous. Key safety features include:

- Pressure relief valves: These automatically let out excess pressure.

- Rupture discs: These burst at a set pressure to release pressure safely.

- Interlock systems: These prevent the reactor from running if conditions are unsafe.

- Emergency shutdown systems can quickly stop the reactor if something goes wrong.

Common Applications in Industry and Research

Chemical Manufacturing

In chemical manufacturing, high pressure autoclave reactors are used to produce a broad variety of chemicals, including pharmaceuticals and plastics. For example, these reactors hydrogenate fats to make margarine. They help make the reactions go faster and produce more products.

Material Science

In material science, these reactors help create new materials with unique properties, like super-strong ceramics and advanced composites. By controlling the reaction conditions precisely, scientists can make materials with desired characteristics, such as high strength or heat resistance.

Oil Refining

In oil refining, high pressure autoclave reactors are used in processes like hydrocracking. High pressure makes these reactions more efficient and improves the quality of the final products.

Pharmaceutical Industry

These reactors are crucial for making active pharmaceutical ingredients (APIs) in the pharmaceutical industry. They help make the reactions faster and more efficient. Autoclaves are also used to sterilize equipment and materials, ensuring the purity and safety of medicines.

Research and Development

Researchers use high pressure autoclave reactors to explore new chemical reactions and develop new materials. These reactors allow scientists to conduct experiments under controlled conditions, leading to discoveries and innovations in various fields.

Conclusion

High pressure autoclave reactors are essential tools in many industries and research areas. They enable chemical reactions that require high pressure and temperature, leading to faster reaction rates and higher yields. Their robust design and advanced safety features make them reliable and safe for producing essential chemicals and materials. As technology progresses, these reactors will continue to play an essential role in science and industry.

To purchase High Pressure Autoclave Reactors, please follow the links.

1 – Techinstro

2 – Shilpent