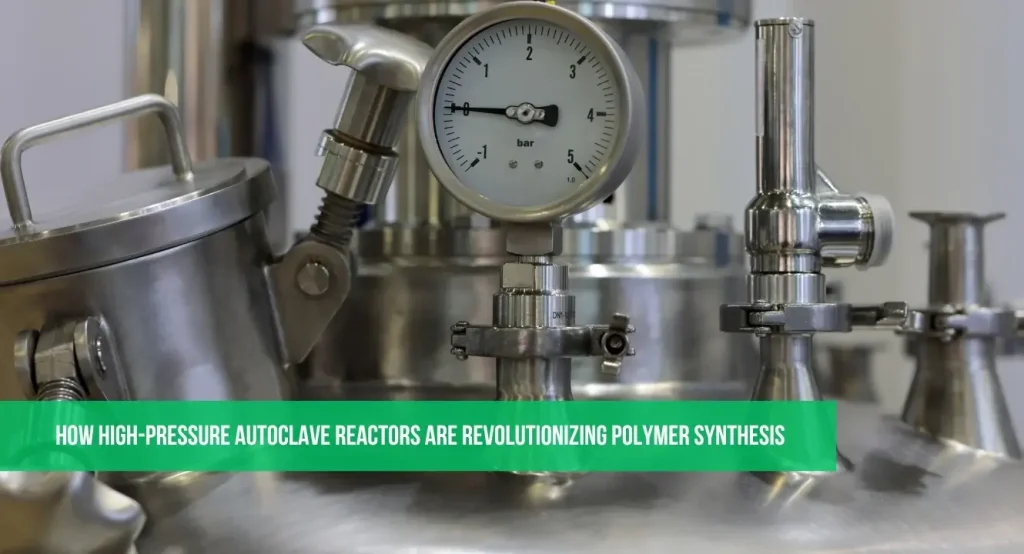

Polymer synthesis creates materials like plastics, rubber, and synthetic fibers essential to our daily lives. High-pressure autoclave reactors are changing the game, making it easier and faster to produce these materials with improved quality and efficiency.

What Is a High-Pressure Autoclave Reactor?

A high-pressure autoclave reactor is a unique machine designed to handle high pressure and temperature chemical reactions. These machines are built with strong materials like stainless steel to endure extreme conditions. They also have advanced controls to ensure accurate pressure, temperature, and mixing monitoring, which helps produce consistent results.

Why Is High Pressure Important for Polymer Synthesis?

Making polymers involves combining smaller molecules, called monomers, into larger ones. High pressure plays a crucial role in this process by:

- Speeding Up Reactions: High pressure makes reactions faster, reducing the time needed to create polymers.

- Enabling Special Reactions: Some polymers can only be made under high-pressure conditions.

- Improving Quality: High pressure helps create uniform polymer chains, which enhances properties like strength, flexibility, and heat resistance.

Looking for High Pressure Autoclave Reactor?

Here is quick links to purchase:

How High-Pressure Autoclave Reactors Are Changing Polymer Production

- More Versatile: These reactors make it possible to create a variety of polymers, including advanced materials like biodegradable plastics and high-performance plastics. Scientists can experiment with different conditions to develop materials with specific properties.

- Better Efficiency: High-pressure autoclave reactors reduce waste and energy use, making polymer production faster and more cost-effective.

- Customizable Processes: With precise controls, these reactors allow scientists to fine-tune the process, resulting in polymers designed for specific industries like automotive, aerospace, or medical devices.

- Eco-Friendly Production: These reactors support green chemistry by enabling the development of biodegradable plastics and polymers from renewable resources, reducing environmental impact.

Real-World Applications

High-pressure autoclave reactors are used in various industries:

- Plastic Manufacturing: Creating strong, lightweight plastics for packaging and construction.

- Textile Industry: Producing synthetic fibers like nylon and polyester with better durability.

- Medical Field: Making biocompatible materials for implants and drug delivery.

- Aerospace and Automotive: Developing heat-resistant, lightweight materials for vehicles and aircraft.

Challenges and Future Directions

While high-pressure autoclave reactors offer many benefits, they are expensive and require skilled operators. Safety is also a significant concern. However, advancements in technology and automation are making these reactors more affordable and easier to use.

In the future, these reactors will continue to play an essential role in polymer science, helping create innovative materials and promoting sustainable manufacturing practices.

Conclusion

High-pressure autoclave reactors are transforming polymer synthesis by enabling the creation of advanced, eco-friendly materials. With their precision and efficiency, they are essential tools in modern industry. As technology improves, these reactors will unlock new possibilities, shaping the materials that define our world.