Introduction to GREEN HYDROGEN

Green hydrogen is a hydrogen fuel type produced using renewable energy sources. It is called “green” because it is generated through environmentally friendly processes that do not emit carbon dioxide (CO2), unlike traditional methods that rely on fossil fuels. One of the key technologies enabling the production of green hydrogen is the high pressure autoclave reactor.

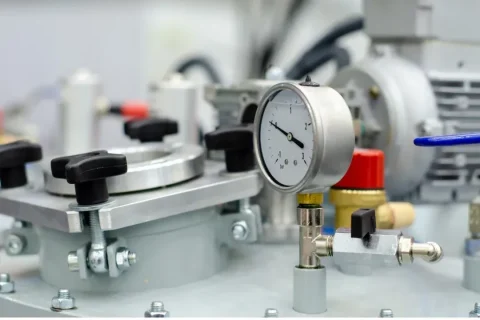

What is a High Pressure Autoclave Reactor?

A high pressure autoclave reactor is a robust vessel designed to conduct chemical reactions at high pressures and temperatures. These reactors are commonly used in chemical, pharmaceutical, and materials science industries due to their ability to control reaction conditions precisely, leading to high efficiency and yield.

How Do High Pressure Autoclave Reactors Work?

High pressure autoclave reactors work by:

Sealing the Reaction Mixture: The reactor is tightly sealed to prevent gases and liquids from escaping.

Applying Pressure and Heat: The reactor is then heated, and pressure is applied, which can be much higher than atmospheric pressure.

Controlling Reaction Conditions: The temperature, pressure, and other reaction conditions are carefully monitored and controlled to optimize the chemical reaction.

Role in Green Hydrogen Production

Green hydrogen production typically involves the process of water electrolysis, where water (H2O) is split into hydrogen (H2) and oxygen (O2) using electricity. The hydrogen produced is considered green when this electricity comes from various renewable sources like wind, solar, or hydro power.

Why Use High Pressure Autoclave Reactors?

Efficiency: High pressure conditions improve the efficiency of the electrolysis process. Under higher pressure, the molecules in the water are more likely to interact with the electrodes, making the reaction faster and more efficient.

High Purity: The controlled environment of the autoclave reactor ensures that the hydrogen produced is high purity, which is essential for many applications, including fuel cells.

Scalability: These reactors can be scaled up to produce large quantities of hydrogen, making them suitable for industrial applications.

Advantages of Using High Pressure Autoclave Reactors

Increased Reaction Rates: Higher pressures lead to faster reaction rates, meaning more hydrogen can be produced in a shorter time.

Improved Energy Efficiency: By optimizing the reaction conditions, less energy is required to produce the same amount of hydrogen, reducing overall energy consumption.

Safety: Modern autoclave reactors are designed with numerous safety features to safely handle high pressures and temperatures.

Real-World Applications

High pressure autoclave reactors are already used in various pilot projects and research initiatives to produce green hydrogen. For example, some renewable energy plants integrate these reactors to convert excess electricity into hydrogen, which can be stored and used later or transported in different applications such as powering hydrogen fuel cell vehicles.

Future Prospects

The use of high pressure autoclave reactors in green hydrogen production is a promising area of research and development. As technology advances, these reactors are expected to become more efficient, cost-effective, and widely adopted, contributing importantly to the global shift towards renewable energy and sustainability.

Conclusion

High pressure autoclave reactors play a crucial role in the production of green hydrogen, offering benefits such as increased efficiency, high purity, and scalability. As we seek sustainable and clean energy solutions, these reactors will likely become a cornerstone in the green hydrogen economy, helping to reduce our carbon footprint and combat climate change.

To buy this product, please follow the links.

2-Shilpent