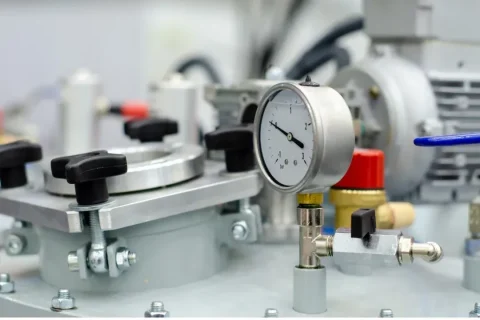

High pressure safety valves are crucial components in various industries where managing high pressure systems is necessary. These valves are designed to protect equipment, systems, and personnel from the dangers associated with excessive pressure levels. When pressure exceeds a set limit, these valves automatically open, releasing the excess pressure and preventing potential damage or accidents. Below are some of the unique features that make high pressure safety valves indispensable in high-risk environments.

Buy High Pressure Safety Valves

Automatic Operation

One of the most significant features of high pressure safety valves is their ability to operate automatically. They do not rely on external power sources or manual intervention. Instead, they are calibrated to activate when pressure levels exceed the pre-determined safe threshold. This ensures immediate response and helps avoid catastrophic events.

Precision Calibration

High pressure safety valves are precisely calibrated to activate at the required pressure level. This calibration process considers the specific requirements of the system they are protecting. The ability to precisely set the activation point is crucial because it allows the valve to release pressure only when necessary, avoiding unnecessary interruptions or pressure losses.

Variety in Materials and Designs

Safety valves for high pressure applications come in various materials, such as stainless steel, brass, and special alloys, designed to withstand the specific conditions they are exposed to. High pressure environments often involve harsh or corrosive substances; thus, materials must be chosen carefully to ensure the valve’s durability and longevity. These valves come in various designs to suit different applications, such as spring-loaded and pilot-operated valves, each serving a unique purpose.

High Temperature and Pressure Resistance

The high pressure safety valve is built to withstand temperatures and pressures simultaneously. This makes it suitable for industries such as oil and gas, chemical processing, and power generation, where extreme conditions are expected. The ability to maintain functionality and reliability under these conditions is a critical feature that sets these valves apart from standard safety valves.

Compact and Robust Design

High pressure safety valves are designed to be compact and robust, making them easy to integrate into various systems. Despite their size, these valves offer high performance and can handle significant pressure levels. Their compact nature ensures they can fit tight spaces, while their robust construction ensures long-term reliability.

Corrosion Resistance

Many high pressure systems involve chemicals that could be corrosive. High pressure safety valves are often made from corrosion-resistant materials or have special coatings to protect against such elements. This feature ensures the valve’s longevity and maintains its ability to operate effectively even in harsh environments.

Adjustability and Customization Options

High pressure safety valves often come with adjustable settings that allow users to fine-tune the pressure release point based on their needs. Some manufacturers also offer customization options, where the valve can be tailored according to a system’s size, material, and specific performance requirements. This adaptability ensures that the valve fits perfectly within the intended application.

Certification and Compliance

High pressure safety valves must adhere to strict industry standards and regulations. These include ASME (American Society of Mechanical Engineers) codes and other international standards. Certification ensures these valves are built and tested to meet safety and quality criteria. This compliance assures industries that the valves they use are safe and reliable for high pressure applications.

Conclusion

High pressure safety valves are critical in safeguarding systems and personnel from the dangers of overpressure. Their automatic operation, precision calibration, high resistance to extreme conditions, and robust designs make them indispensable in many industries. By understanding their unique features, industries can choose the correct valve for their applications, ensuring safety and operational efficiency.

These unique characteristics underscore the importance of high pressure safety valves, making them essential components in environments where safety and reliability are paramount.