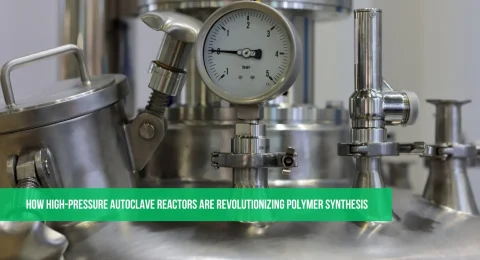

High-pressure autoclave reactors are like super-strong cooking pots used in labs and factories to make chemicals, medicines, and materials. Because they work under extreme pressure and heat, they can be dangerous if not handled properly. This guide explains simple safety steps to prevent accidents.

High-Pressure Autoclave Reactors Safety: Avoiding Explosions

- Pressure Relief Systems

- Emergency vents (rupture discs): Like a safety valve on a pressure cooker, these burst open if pressure gets too high.

- Backup pressure releases: Extra safety valves in case the first one fails.

- Automatic shutdown: The reactor stops working if pressure or temperature becomes unsafe.

- Regular Checks

- Test safety valves every few months.

- Use gauges and sensors to monitor pressure 24/7.

Strong Materials: Preventing Breaks & Leaks

- Choosing the Right Metal

- Special metals like Hastelloy or Titanium resist rust and cracking.

- Some reactors have ceramic or Teflon linings for extra protection against harsh chemicals.

- Checking for Weak Spots

- Regular ultrasound scans (like medical ultrasounds) check for hidden cracks.

- Hydrostatic testing fills the reactor with water at high pressure to ensure no leaks.

Leak & Explosion Prevention

- Sealing Tight

- Double-sealed doors & lids prevent dangerous leaks.

- Magnetic stirrers (no holes in the reactor) stop leaks in mixing systems.

- Explosion Safety

- Gas detectors sound alarms if flammable gases (like hydrogen) escape.

- Explosion-proof motors & wiring prevent sparks near flammable chemicals.

Temperature Control: Avoiding Overheating

- Cooling Systems

- Water jackets (like a cooling sleeve) keep temperatures stable.

- Emergency cool-down injects cold liquid if things get too hot.

- Even Heating

- Good stirring prevents hot spots.

- Automatic temperature control adjusts heat as needed.

Safe Operation: Protecting Workers

- Training & Rules

- Workers must learn startup, shutdown, and emergency steps.

- Lockout/Tagout (LOTO): Locks prevent accidental startup during repairs.

- Remote Monitoring

- Sensors send alerts to computers or phones if something’s wrong.

- Some reactors can be controlled from a safe distance.

Emergency Plans

- If Something Goes Wrong

- Safe venting systems release pressure without spraying chemicals.

- Secondary containment (like a backup tank) catches leaks.

- Learning from Mistakes

- After any incident, find the cause and fix it.

- Regular safety drills prepare workers for emergencies.

Final Thoughts

High-pressure autoclave reactors are powerful tools but need careful handling. By using strong materials, safety valves, leak detectors, and proper training, we can use them safely.