The evolution of high-pressure reactors in pharmaceutical synthesis is a fascinating journey of technological advancement. This article aims to explain this evolution in a way that’s easy to understand, even for those without a background in chemistry or engineering.

The Early Days: Discovery and Basic Applications

The story of high-pressure reactors in pharmaceutical synthesis begins in the early 20th century. Initially, these reactors were essential vessels capable of withstanding higher pressures than standard laboratory equipment. Scientists discovered that specific chemical reactions, impractical or too slow at atmospheric pressure, could be significantly accelerated under high pressure.

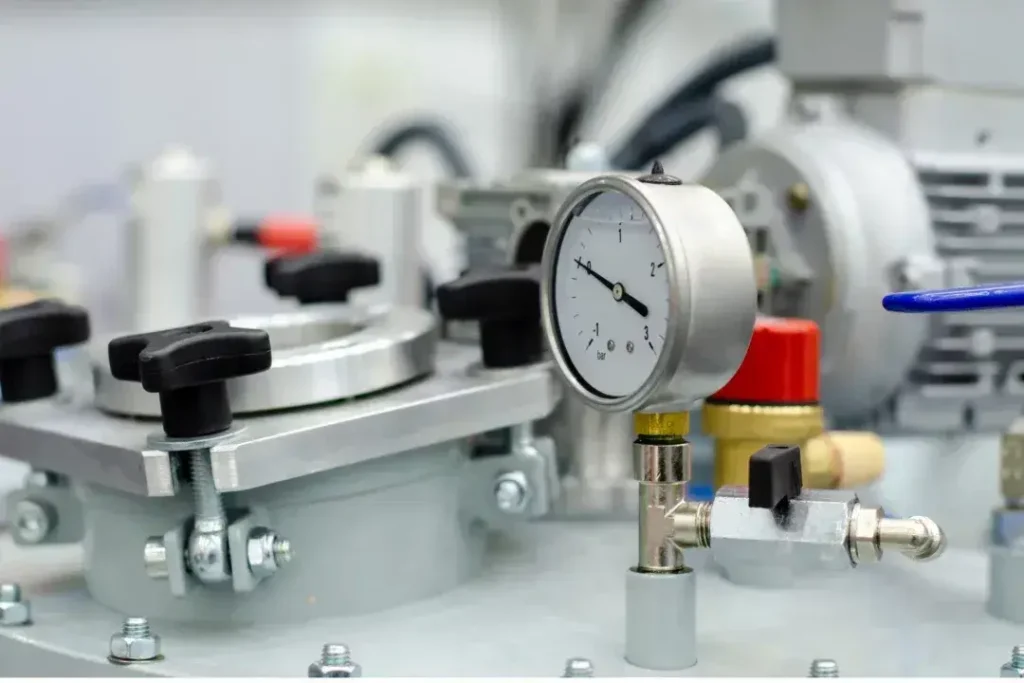

Advancements in Design and Safety

As the pharmaceutical industry grew, so did the need for more efficient and safer reactors. The mid-20th century saw significant improvements in the design of high-pressure reactors. These advancements included better materials that could withstand higher pressure, corrosive substances, and extreme temperatures. Safety valves, pressure relief systems, and robust control mechanisms became standard, ensuring reactions could be conducted more safely.

The Role of High Pressure in Synthesis

High-pressure reactors play a crucial role in pharmaceutical synthesis by allowing for otherwise impossible reactions. Under high pressure, molecules are forced closer together, which can increase the reaction rate or enable entirely new pathways for creating compounds. This is particularly crucial in synthesizing complex molecules often found in modern drugs.

Modern High-Pressure Reactors: Automation and Precision

Today’s high-pressure reactors are marvels of engineering. They are often automated, allowing precise control over pressure, temperature, and reaction duration. This precision is vital in pharmaceuticals, where the purity and consistency of a drug’s active ingredients are paramount. Modern reactors can also handle a broader range of reactions, making them indispensable drug development and production tools.

The Future: Sustainability and Innovation

Looking forward, the evolution of high-pressure reactors will likely focus on sustainability and efficiency. There’s a growing interest in using these reactors for reactions that are faster and more environmentally friendly. Innovations may include better catalysts that work under high pressure, reducing the need for hazardous solvents and energy-intensive processes.

Availability:

Its available at shilpent’s website you can visit through this link to purchase high pressure autoclave reactor.

Conclusion

The evolution of high-pressure reactors in pharmaceutical synthesis is a journey from superficial pressure vessels to sophisticated, automated systems that play a crucial role in drug development. This evolution has enhanced the efficiency and safety of pharmaceutical synthesis and opened new avenues for creating life-saving medications. As technology advances, we can expect these reactors to become even more integral to the pharmaceutical industry.