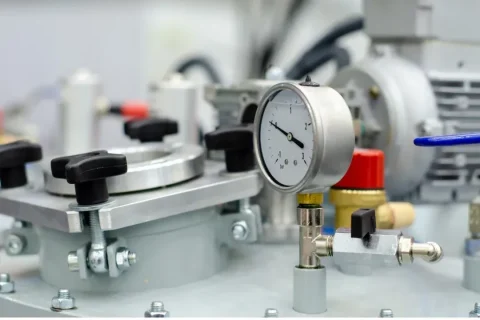

A high-pressure autoclave reactor is a special type of equipment used in laboratories and industries for chemical reactions under high pressure and temperature. It stands out because of its ability to handle extreme conditions, making it ideal for producing high-quality products, accelerating reactions, and safely carrying out complex processes.

Main Highlights:

- Handles High Pressure: Unlike regular reactors, high-pressure autoclave reactors are designed to be operated at high pressures, sometimes reaching several hundred bars. This is crucial for reactions that require pressurized environments to occur efficiently.

- Withstands High Temperatures: These reactors can also handle very high temperatures, often necessary for speeding up chemical reactions or breaking down rigid materials.

- Durability and Safety: Made from solid materials like stainless steel or special alloys, these reactors are built to last and ensure safety, even in extreme conditions. Their design minimizes the risk of accidents, which is critical in high-pressure environments.

- Controlled Environment: The reactor allows precise control over pressure, temperature, and other reaction conditions. This helps researchers and engineers optimize processes and achieve better outcomes.

- Versatility: High-pressure autoclave reactors can be used in various fields, from synthesizing new materials in laboratories to chemical production in industries. They are also helpful in pharmaceuticals, energy, and materials science.

Buy High Pressure Autoclave Reactor

Key Unique Features of High-Pressure Autoclave Reactors (Elaborated)

High-pressure autoclave reactors are designed to perform chemical reactions requiring extreme conditions, such as high pressure and temperature. Here’s a closer look at the unique features that set them apart from other reactors:

Ability to Handle High Pressure

- What it means: These reactors are built to operate under very high pressures, sometimes reaching hundreds or even thousands of bars. In comparison, regular reactors can only manage much lower pressures.

- Why it’s unique: Many chemical reactions, especially those involving gases, need high pressure to proceed efficiently. High-pressure autoclave reactors create an environment where molecules are forced to interact more, speeding up the reaction or making it possible when low pressure wouldn’t work.

Withstands High Temperatures

- What it means: Besides handling high pressure, these reactors can withstand very high temperatures, often reaching several hundred degrees Celsius.

- Why it’s unique: Many reactions only happen at high temperatures. High temperatures can break down rigid materials or speed up chemical reactions. Regular reactors may not survive such heat, but autoclave reactors are made with unique materials to prevent damage.

Built for Durability and Safety

- What it means: High-pressure autoclave reactors are constructed from materials like stainless steel, titanium, or special alloys that can endure the harsh conditions inside the reactor.

- Why it’s unique: Handling high pressure and temperature can be dangerous if the equipment is weak or poorly designed. These reactors are built to be extremely strong and safe, reducing the chances of leaks or explosions, which is essential when working in extreme environments.

Precise Control Over Conditions

- What it means: These reactors allow users to accurately control critical reaction conditions like temperature, pressure, and stirring speed.

- Why it’s unique: Precise control allows researchers and engineers to fine-tune reactions for the best possible outcome. It’s beneficial for studying how materials behave under different conditions or developing new chemical processes. This level of control is more challenging to achieve in simpler reactors.

Versatility Across Different Fields

- What it means: High-pressure autoclave reactors can be used for various applications like pharmaceuticals, energy production, material science, and more.

- Why it’s unique: These reactors’ versatility allows them to be used in many different industries. Whether producing new drugs, studying advanced materials, or exploring alternative energy sources, high-pressure autoclaves are essential for conducting experiments and processes that require extreme conditions.

Increased Reaction Efficiency

- What it means: By combining high pressure and temperature, autoclave reactors can make chemical reactions happen faster and more efficiently than in regular reactors.

- Why it’s unique: This increased efficiency is essential for industrial processes, as it can save time and resources. It also makes specific reactions that wouldn’t occur at lower pressures and temperatures possible.

In summary, the high-pressure autoclave reactor’s ability to handle extreme conditions and its safety, precision, and versatility make it a standout tool in research and industrial applications.