In the world of pharmaceutical manufacturing, how medicines are made can be just as important as the medicines themselves. Two essential methods used in creating drugs involve high-pressure reactors: batch processing and continuous flow. Both have benefits and challenges, especially when making medicines safely and efficiently.

What is Batch Processing?

Think of batch processing, like baking cookies in an oven. You prepare a single batch, put it in the oven, wait for it to bake, and then take it out before starting the next one. In pharmaceutical manufacturing, batch processing means mixing all the ingredients (chemicals) in a reactor, reacting, and removing the product before starting the next batch.

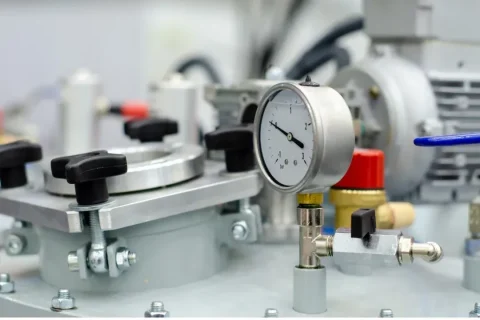

Checkout the following two shortlisted High Pressure Autoclave manufacturing companies.

Pros:

- Flexibility: Batch reactors can switch between making different drugs, which is excellent for companies that make a variety of medicines.

- Simplicity: They are generally easier to set up and operate, making them a good choice for more straightforward chemical reactions.

Cons:

- Time and Efficiency: Each batch takes time to set up, react, and clear out, which can slow down production.

- Quality Variation: There can be slight differences between batches, affecting the medicine’s quality.

What is Continuous Flow?

Continuous flow is more like a conveyor belt in a factory. The ingredients continuously move through a reactor where the chemical reaction happens. As they exit, new ingredients enter, making it a never-ending process.

Pros:

- Efficiency: This method can produce medicines faster and more consistently because it doesn’t stop and start like batch processing.

- Control: It’s easier to maintain consistent quality since the reaction conditions (like temperature and pressure) always stay the same.

Cons:

- Complexity: Continuous flow systems can be more complex and expensive to set up.

- Flexibility Issues: They need to be more flexible when changing between different types of medicine production.

Implications for Pharmaceutical Manufacturing

- Product Quality: Continuous flow can offer more consistent quality, which is crucial in medicine, where every batch must be perfect.

- Speed of Production: Continuous flow could be the better option if medicine needs to be made quickly (like in a health crisis).

- Cost: Batch processing might be cheaper and more straightforward for smaller-scale or less frequent production runs.

- Scalability: Continuous flow might be more efficient and cost-effective in the long run for large-scale production.

Conclusion

Choosing between batch and continuous flow in high-pressure reactors depends on what kind of medicine is being made, how much is needed, and how fast it’s needed. Batch processing offers flexibility and simplicity, making it suitable for a wide range of products and smaller-scale operations. Continuous flow, on the other hand, excels in large-scale, consistent, and efficient production, especially for high-demand medicines. As pharmaceutical manufacturing continues to evolve, we might see more companies adopting a mix of both methods to get the best of both worlds.