High pressure autoclave reactors are essential for various industrial processes, including chemical manufacturing, pharmaceuticals, and materials science. These reactors operate under extreme conditions, with high pressures and temperatures, making material selection a critical factor. Choosing the suitable materials ensures the reactor’s safety, longevity, and efficiency. Here, we explore the challenges in selecting materials for high pressure autoclave reactors and provide some practical solutions.

Challenges in Material Selection

Corrosion Resistance

One of the challenges is finding materials that can withstand the corrosive nature of many chemical reactions:

Chemical Corrosion: Many reactions involve aggressive chemicals that can corrode materials, leading to leaks and failures.

High Temperature Corrosion: High temperatures can accelerate the corrosion process, making it harder to find suitable materials.

Mechanical Strength

The materials must be strong enough to withstand the high pressures inside the reactor:

Pressure Resistance: Materials must maintain integrity under high pressure to prevent catastrophic failures.

Fatigue Resistance: Repeated pressure cycles can weaken materials over time, so they must resist fatigue.

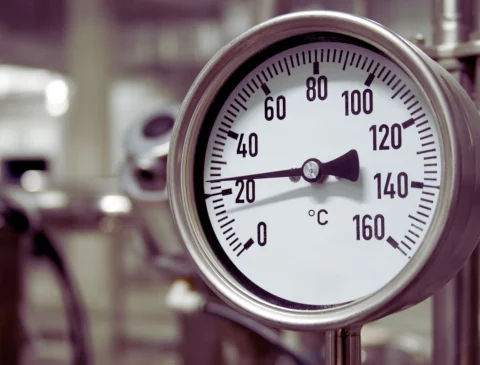

Thermal Stability

Materials need to maintain their properties at high temperatures:

Heat Resistance: High temperatures can cause materials to weaken or deform, so they must be thermally stable.

Thermal Expansion: When things heat up, different materials expand at different rates. This can lead to stress and even failure. Let’s consider how heat affects different materials.

Compatibility

The materials must be compatible with the specific chemicals used in the reactions:

Chemical Compatibility: Materials must not react with the chemicals used, as this can contaminate the product and damage the reactor.

Gasket and Seal Compatibility: The seals and gaskets must also be made from materials that can withstand the same conditions as the reactor body.

Solutions for Material Selection

Stainless Steel

Stainless steel is a good choice because of its balance of strength, corrosion resistance, and affordability:

Types: Grades like 304 and 316 stainless steel resist many chemicals and high temperatures.

Usage: Suitable for many general applications but may need to be more adequate for highly corrosive environments.

Nickel Alloys

Nickel alloys offer superior corrosion resistance and strength:

Inconel: Known for its excellent high-temperature strength and resistance to oxidation and corrosion.

Hastelloy: Offers outstanding resistance to a wide range of aggressive chemicals and high temperatures.

Titanium

Advantages: Excellent for applications involving strong acids and chlorides.

Disadvantages: More expensive than stainless steel and nickel alloys, making it suitable for specific high-corrosion environments.

Specialty Coatings

Applying specialty coatings can enhance the properties of base materials:

PTFE (Teflon) Coatings: Provide excellent chemical resistance but may not be suitable for high temperatures.

Ceramic Coatings: Offer high-temperature resistance and chemical stability but can be brittle.

Composite Materials

Advanced composite materials can combine the benefits of different materials:

Carbon Fiber Composites: Provide high strength and corrosion resistance with a lighter weight.

Glass-Lined Steel: Combines steel’s strength with glass’s chemical resistance.

Regular Maintenance and Monitoring

Even the best materials can degrade over time, so regular maintenance and monitoring are crucial:

Inspections: Regularly inspect the reactor for signs of wear and corrosion.

Preventive Maintenance: Replace worn parts before they fail to avoid unplanned downtime and ensure safety.

Monitoring Systems: Use sensors and monitoring systems to detect early signs of material degradation.

Conclusion

Selecting suitable materials for high pressure autoclave reactors is a critical task. The materials must withstand high pressures, extreme temperatures, and corrosive chemicals while maintaining integrity and performance. Stainless steel, nickel alloys, titanium, specialty coatings, and composite materials each offer unique advantages and can be taken based on the application’s specific requirements. Regular maintenance and monitoring further ensure the reactor’s longevity and safety. By addressing these challenges with the right solutions, industries can achieve efficient and reliable reactor operations, driving innovation and productivity.

To purchase High Pressure Autoclave, please follow the links.

2-Shilpent